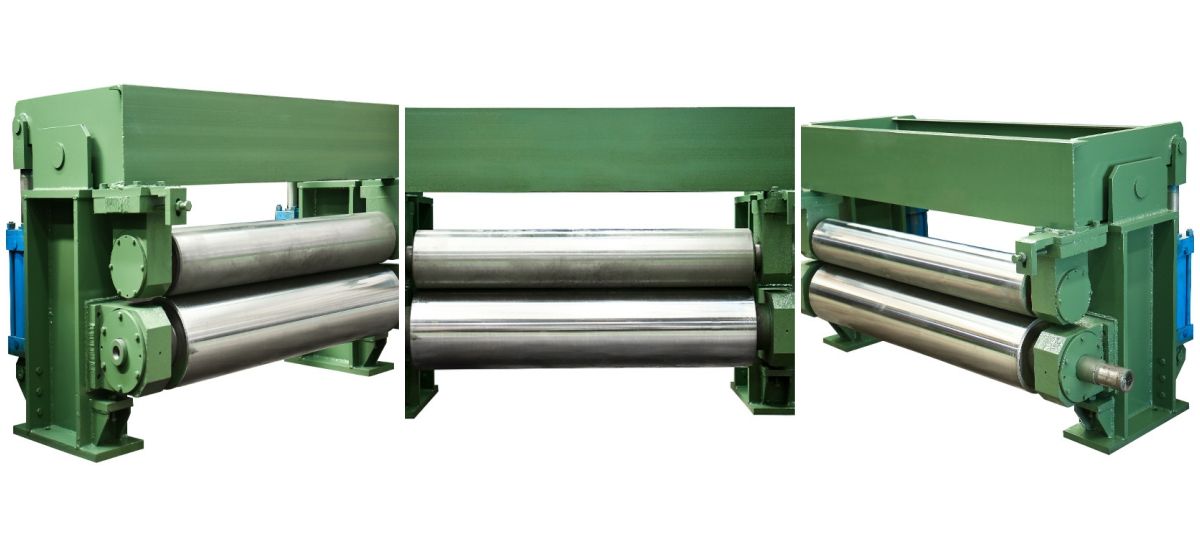

The pinch roll is usually composed of roll body, roll shaft, bearing, sealing cover, connecting piece and other components. Its working principle is to drive the roll body to rotate through an electric motor, and deliver the goods or materials to the designated position through friction.

Introduction

The process of producing pinch rolls in factories generally includes raw material procurement, cutting and processing, welding and assembly, spraying and coating, debugging and testing, and other links. During the production process, factories generally strictly control product quality to ensure that each clamping roll meets standard requirements.

our abilities

Firstly, the equipment has efficient production capacity. We adopt advanced technology and processes, equipped with high-quality equipment, to efficiently and stably complete the tasks of product transportation and positioning, ensuring the continuous operation of the production line.

Secondly, the equipment has good quality control capabilities. The clamping roll equipment produced by the factory adopts high-quality materials and precision processing technology to ensure the stability and durability of the equipment. The equipment will undergo strict quality inspection and testing to ensure that every aspect of the product meets the standard requirements.

In addition, the device has flexible customization capabilities. The clamping roll equipment produced by the factory can be customized and designed and manufactured according to the actual needs and production requirements of customers, which can meet the production needs of different industries and products.

Production advantages of pinch rolls:

1. High work efficiency: The pinch roll can stably and quickly transport goods or materials, improving production efficiency.

2. Effort saving and Energy saving: Compared to manual handling, pinch rolls can reduce labor costs and save energy resources.

3. Flexible and diverse: The clamping roll can be customized and designed according to different needs, suitable for various working environments and conveying tasks.

4. Long service life: The material of the pinch roll is excellent, and after precision processing, it has a longer service life and improves work efficiency.

Overall, the pinch roll equipment we produce has various capabilities such as high efficiency, stability, durability, precision, and flexibility, providing important support and guarantee for the production of customer factories. If you are interested in our products, please feel free to consult at any time~